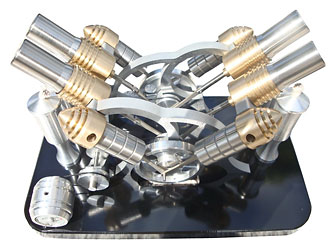

6-cylinder Stirling Engine Improvements Update

6 cylinder Stirling engine update by Approtechie

Approtechie just uploaded an update on the improvements made to his 6 cylinder Stirling engine! If you’ve seen his other videos you’ll be able to pick out the changes.

He adjusts the air pressure in the 6 cylinder Stirling engine while it’s running and you can see a dramatic change in performance. I knew adding pressure to Stirling engines aided in performance but I’ve never seen pressure increased during operation. It’s a dramatic change to say the least.

His mentions in his description that he would like to test this 6 cylinder Stirling engine in a small canoe. I think it’s going will be more than enough.

I would say his improvements have are so good that his engine is on the verge of tearing itself apart. I think the next step in development will be to strengthen the structure of the 6 cylinder Stirling engine to cut vibrations.

I’m looking forward to his next video about the 6 cylinder Stirling engine. As always Approtechie is an inspiration!

Test run after improvements

6 cylinder Stirling engine video description

"I’ve had to do a number of tweaks and repairs to this engine including:

- Add balancers to the crank.

- Re-glue all power piston guide rods since they all came loose.

- Add wood supports to power piston brass guide tubes since they all broke loose, too.

- Seal rubber inner tube cooling section with RTV silicone on each cylinder.

- Wrap fiberglass stove rope around each cylinder above the heat shield to protect the inner tube rubber from the heat.

- Add a lower heat shield (piece of aluminum gutter) to protect the wood base from heat.

- Build a 6-burner propane heater from iron pipe, a fireplace log lighter gas valve, a 20-pound tank with regulator, and 6 brass wok burner nozzles (about $1.50 each from Ebay) threaded into the pipe.

- Double the bearings on the outside supports to limit shaft wobble from power strokes.

- Seal air leaks around and in the bellows.

- Install 3 thin plastic rings cut from PVC fittings into the grooves inside each bellows to prevent them from collapsing under negative internal pressure.

- Add a small air pump to be able to pressurize the cylinders a bit. I think this could eventually be attached to a jack shaft and run off the crank to maintain some pressure in the cylinders since the air leaks out pretty quickly from the displacer rod guides.

- Install multi-groove pulley on crank to drive applications at varying speeds.

- Paint heat shield with heat-resistant paint – the original stuff burned off.

- Install aluminum flex pipe for smoke stack – used on cars for hot air intake from exhaust manifold.

The engine is running pretty well now, finally. You can see that when it’s idling along at around 400 rpm with a small flame and then I open the gas valve, it responds quickly and passes 1100 rpm in about 20-25 seconds. I’ve had it over 1200 rpm but I don’t see much point in going beyond that – I’d rather load it down and make it work hard at a lower rpm where it develops more torque. I think it would interesting to try driving a small canoe with this engine, I believe it has the power to do it.

I’m wanting to test the power output now that it seems to run consistently pretty well, and am building a new Prony brake to test it soon. Stay tuned!"

More of Approtechie’s Videos

You can find more of Approtechie’s videos including his 6-cylinder Stirling engine at his Technology for Development YouTube Channel. His ingenious engines and inventions are fun and interesting. His creations are built in

"A search for inexpensive practical ways to help folks meet their own basic needs, especially in developing countries."